The advantages of brass forging

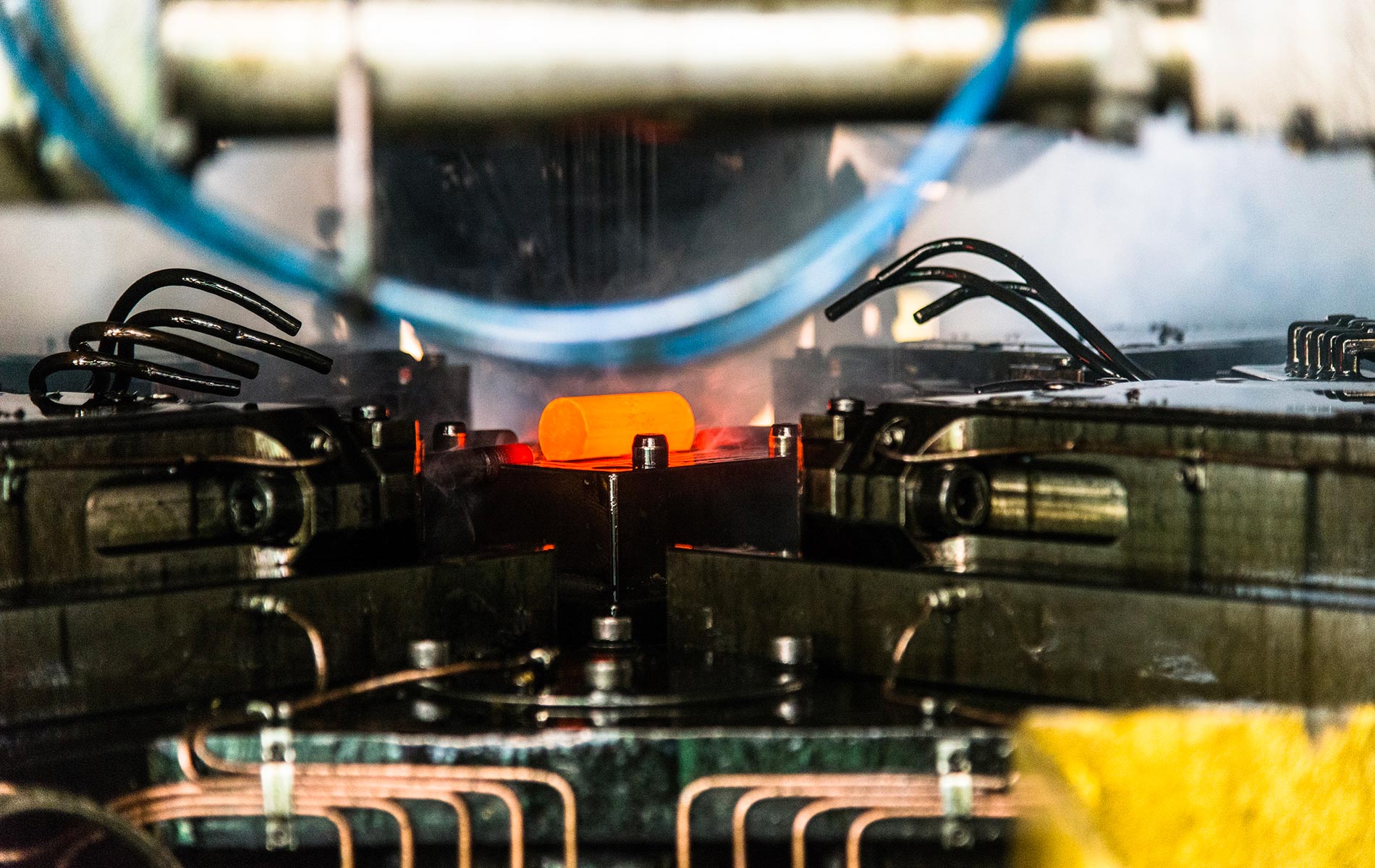

The ever increasing spread of components made from non-ferrous metals by the building industry (plumbing), the furnishing industry (handles), the household appliances, the electrotechnical industry and the automotive industry, etc. has required producers to direct themselves towards the hot pressing technique which uses brass rod as its raw material, modern heating techniques, high output mechanical presses and special sub-presses to produce cavity cored and complex components simply and efficiently.

This process offers many advantages in comparison with the traditional casting techniques.

- low incidence of Manpower: only three operations, stamping, trimming and sandblasting, against many phases like forming, casting, shakeout, knockdown, trimming, sandblasting, core preparation (for components with corings), sand recycling, etc.

- low material consumption in relation to finished quantities (flash reduced to a minimum)

- low scrap percentage

- uniform density of material with consequent reductions in thickness and weight

- low tool consumption in machining thanks to absence of sand and Impurities on the surface of the components

- security of high homogeneity in the alloy composition, primarily due to the inability to recycle "scrap" components

- high production volumes in relation to investment

- mechanical strength of components due to the “grain flow" obtained by progressive deformation

- consistency of dimensional accuracy

- freedom from porosity

- sharp definition of profiles.